What is Honing Machine Process?

Metalworking is a process that uses machinery to shape or cut metal. There are a variety of different methods for doing this, but one of the most popular is honing machine process. This process uses a specially designed machine to create a smooth, consistent surface on metal parts. The honing machine can be used on a variety of different metals, including steel, aluminum, brass, and copper. Honing machines are tools designed to clean and smooth metal using hard tools and rough stones as abrasives.

The honing process was developed to allow for the improvement of bore geometry, size control, surface finish, and surface structuring. The honing process provides the final sizing and uses the specified surface finish in the interior of a tubing or cylinder bore. Finishing is accomplished by using abrasive stones of suitable grit and grade to polish the work surface. The stones are rotated and reciprocated on the rock grinder under controlled pressure to produce cross-hatch patterns on the surface of the part honed.

Characteristics of Honing Process:

- It is a low velocity, highly accurate process.

- Honing process generates a cross-marked surface on the workpiece. This workpiece is used to hold lubricants.

- It can be used for correcting the roundness of the hole.

- High tolerance of 2 to 3 microns can be achieved.

- Both hard and soft materials can be honed.

- The range of cutting speed varies from 0.25 to 1m/s.

- The cutting angle ranges from 60 to 90o.

- The pressure applied on the lateral surface area of the workpiece during the honing process ranges from 1000kPa to 2500kPa.

Honing is a machining process that uses a type of grinding wheel called a honing stone to produce a precision surface on metal parts.

The process is used to improve the accuracy and finish of components such as shafts, gears, bearings, and cylinders. The honing process works by passing the workpiece (metal part) over the rotating honing stone. This action causes the honing stone to remove small amounts of material from the surface of the workpiece. As the workpiece is passed over the honing stone, it is gradually refined until the desired finish is achieved.

Honing Machine Types:

There are two types of honing machines:

A vertical honing machine is a precision tool used to improve the surface finish and dimensional accuracy of metal parts. The machine consists of a base, column, and headstock. The workpiece is mounted on the headstock and rotated while a grinding wheel or other abrasive tool is moved up and down the length of the part. This type of machine can be used to produce very smooth surfaces with tight tolerances.

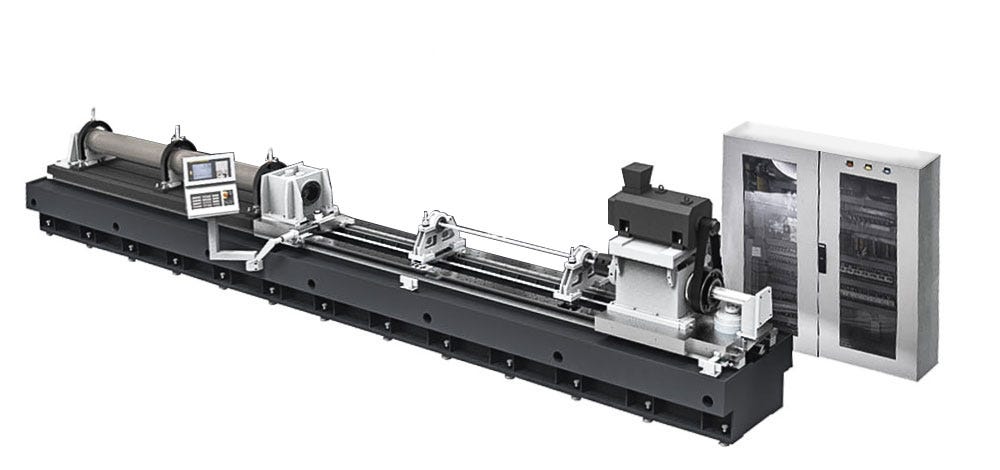

A horizontal honing machine is a precision tool used to improve the surface finish and accuracy of metal parts. The principle of operation is similar to that of a lathe, with the part held between two rotating abrasive stones. However, the part is usually much smaller in diameter than the stones, which allows for greater accuracy and finish. Horizontal honing machines are used in a wide variety of applications, from machining medical implants to polishing golf clubs.

- It can be used for finishing automobile crankshafts

- Honing process is used for finishing gears in the automobile industry.

- It is also used for production purposes where hollow cylindrical bores must be accurately finished.

- It is also used for finishing the internal diameter of the IC engines.

- It can be used for improving hole roundness.

Comments

Post a Comment